Marzocchi GS Forks

The R80GS and R100GS (from 1987) were equipped with 40mm Marzocchi forks. From the manual: "Long-stroke, responsive telescopic fork with independent-action hydraulic compression and extension damping, progressive spring rates and integral fork stabilizer." Long stroke is the 225mm nominal stroke, although that includes the top-out spring; the functional stroke is about 210mm. Independent action is the left leg having travel-dependent damping (stiffer as the forks compress more) while the right has primarily rebound damping with a valve. The stock spring does offer a progressive rate toward the very bottom of the stroke, and the fork brace is much improved over that from the G/S model.

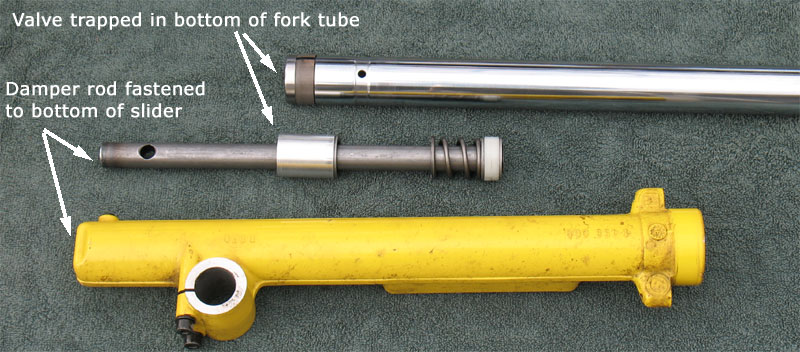

Here's how the fork is constructed. The damper rod is bolted to the bottom of the fork slider (that's the bolt on the very bottom) and the valve is clipped into the end of the fork tube. When the forks compress, the damper rod slides up through the valve. Likewise, when they extend, the damper rods extends through the valve.

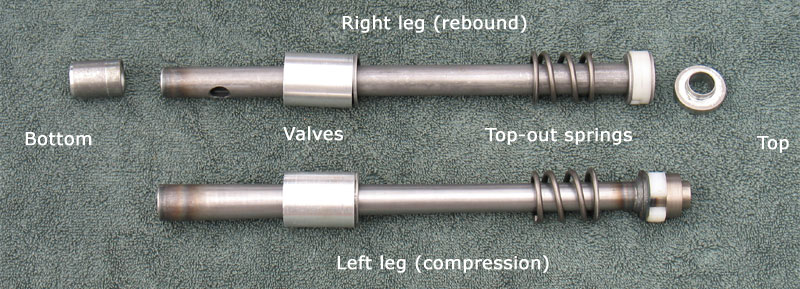

Moving on, to focus on the damper rod assemblies themselves. While the fork tubes and sliders are functionally the same from left to right, the damper unit in each side is different.

In both cases the valve (the aluminum body and the disc) is retained in the bottom of the fork tube. The damper rod is fastened to the bottom of the slider, so when the fork extends the rod moves through the valve, to the left in the picture above, ultimately compressing the top-out springs between the valve and the upper end of the damper rod. When the forks are compressed, the rod moves to the right until the bottom of it is nearly flush with the bottom of the valve.

The extra bit on the left side is a sleeve that fits over the bottom end of the rebound damper rod and provides a hydraulic bottoming stop, known commonly as a bottoming cone. At the upper right is the spring seat for the main spring on the rebound leg. The seat for the spring on the compression leg is part of the damper rod.

All of these parts are immersed in oil, and the fork damping is determined by the way the oil is moved as the fork extends or compresses. There are two principle movements of oil: across the valve, and in and out of the damper assembly. I'll call these primary and secondary flow. The total damping is basically the combined effect of all fluid friction.

Primary flow: Oil moving across the valve is easy to visualize in the picture above, by simply imagining the valve sliding back and forth with an imaginary fork tube providing walls on each side. When the forks are compressed, the valve is to the left and all of the fluid is to the right. Whe they are extended, the valve is to the right and the oil is all to the left. Since the valve body is fitted tightly into the tube, all of that oil has to flow between the valve and the damper rod as the fork moves. This is between 5 and 6.5cc of oil per centimeter of fork travel.

Secondary flow: Some oil has to leave the damper assembly because as the fork compresses the volume that's taken up by the wall of the fork tube displaces oil, pushing it above the damper and into the area where the main fork spring is (to the right of the illustration). When the fork extends, it withdraws oil from the spring area to refill the damper. This amount of oil doesn't represent the entire volume of the fork during that compression, only the volume that the walls of the fork tube require. On these forks, that's about 3.5cc of oil per centimeter of fork travel.

The total damping effect is controlled by the speed of the oil being forced through various gaps and the size of the opening. While every movement of oil within the fork contributes to the damping, it's my conclusion that the vast majority of the rebound damping happens in the primary flow of the right leg, and the majority of the compression damping happens in the primary flow of the left leg. Neither side restricts the secondary flow. Most of the pertinent dimensions are given so that you can form your own conclusions; a better answer can only come from a shock dynamometer.

Rebound leg

The valve body contains a check valve which lets oil flow easily from bottom to top, but less easily from top to bottom. The working part of the oil is trapped between the valve and the white piston ring at the top. As the forks extend, oil is forced between the damper rod and the inner diameter of the closed valve. When the forks compress, the force of oil from the bottom lifts the valve and allows relatively free flow back into the damper area. The working part of this damper is between the valve and the piston.

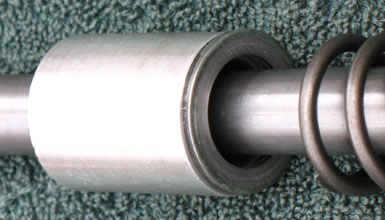

The spring holds the valve disc (in the middle of the right-hand picture) against the seat, which is the step in the aluminum body. Oil flowing from top to bottom must go between the damper rod and the inside of the valve disc. When the fork compresses, the oil lifts the disc off the seat and flows around the outside. The three prongs on the upper ring limit the movement of the disc and maintain the oil flow path when the valve is open.

Secondary flow is handled by the hollow damper rod. The holes at the bottom and the opening at the top allow unimpeded flow in both directions.

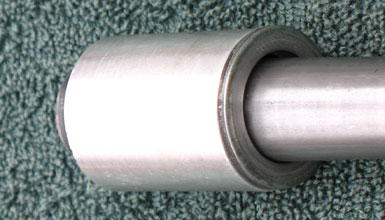

Additionally, there's a simple anti-bottoming feature at work. As the fork bottoms out, the damper rod hole is closed off and oil is trapped in the bottom of the fork between the bottom of the valve and the end of the slider. This creates a cushioning effect as the oil forces its way through the very small gap between the valve and the end of the rod. In the picture to the right, the space around the steel cap on the end of the damper rod (look at the first picture on the page to better visualize this) represents the trapped oil volume.

When the fork is assembled and filled with oil, with no spring installed, the rebound damping and anti-bottoming can both be felt when moving the fork by hand.

| Rebound dimensions | |

|---|---|

| Damper rod OD | 20mm |

| Valve disc ID | 20.5mm |

| Valve body ID | 25.2mm |

| Valve disc OD | 27.6mm |

| Valve chamber ID | 30.4mm |

Compression leg

The valve is actually just an aluminum cylinder with a slight taper in the inside, facing the bottom. The steel disc is the same size as the aluminum cylinder; it's there to protect the aluminum from the top-out spring.

As the forks compress, the gap between the rod and the valve gets smaller, resulting in an increaing damping effect.

Since the damper rod has no holes in it, secondary flow happens at the upper end of the damper rod. Oil simply flows in and out of the damper area by flowing around the edge of the blue-colored steel disc, which is smaller than the inner diameter of the fork tube. The white plastic bushing keeps the disc centered in the fork tube while still allowing flow. On this side, the working part is between the valve and the bottom of the fork.

It's difficult to get a feel for the compression damping with the fork off the bike. Compression damping is intended to control very fast fork movements, and you're not going to simulate that by hand in your garage. When the fork is assembled, with oil in it but no springs,you will feel the damping increase as the leg is compressed more. This effect is the same for both compression and rebound. The effect increases at the very bottom to provide the sort of anti-bottoming that the rebound leg has.

| Compression dimensions | |

|---|---|

| Damper rod max diameter | 23mm |

| Damper rod min diameter | 18mm |

| Valve & disc ID | 23.7mm |

| Upper disc (secondary flow) | 32mm |

| Fork tube ID | 34mm |

Springs and spacers

The stock springs are slightly progressive, about 445mm long with a slight diameter reduction at one end (should be at the bottom), and are used with 159mm spacers (169mm for the PD). A spacer/seat disc fits into the bottom of the spring on the rebound side. The forks have about 565mm fork space, so with the 159mm spacers there is about 40mm spring preload.

There are many aftermarket springs available, and there is no particular magic to what works. The outer diameter should be as close to 33mm as possible without being larger, they need to allow the amount of travel you need (the forks normally permit 210mm), they should have the spring rate you want (stock is just under 5 N/mm but the aftermarket will provide up to about 9) and they need to be preloaded to give you the ride height you want. A sampling of some springs I have found are shown here.

| Name | Length (mm) |

Diameter (mm) |

Wire dia (mm) |

Coils1 | Weight (g ea) |

Rate N/mm |

Travel (mm)2 |

Notes |

|---|---|---|---|---|---|---|---|---|

| OEM | 445 | 33 | 4.5 | 36 | 420 | 4.9~8.3 | 270 | 10x9 + 20 taper + 6x6 Rate rises4 around 175mm fork compression |

| Unknown (came with spare forks) |

575 | 32 | 4.9 | 54 | 685 | 5.4~10 | 300 | 18x8 + 20 taper + 15x2.5 Rate rises around 125mm |

| Progressive? (per gunsmoke.com) |

~575 | 51 | 28 wide coils + 23 close coils | |||||

| RaceTech S3234085? | 340 | 32 | 4.8 | 31 | 390 | 8.3 | 1753 | Straight-rate. Made for a K-bike, too short for the GS. |

| Wirth? | 575 | 32 | 5.0 | 58 | 5.4~7.5 | 310+ | 25x6.8 + 33 decreasing to 1.8mm Rate rises around 95mm |

|

| Progressive? (per Jason Adams) |

575 | 32 | 5.0 | 56 | 750 | 5.5~8.8 | 290 | 22x7 + 34 decreasing to 1mm Rate rises around 45mm, maybe during sag. |

| HyperPro 0265 | 620 | 33 | 63 | 4.5~10.6 | Starting rate around 6 Nm installed Reaches maximum rate around 168mm total |

|||

| HyperPro 2020 | 598 | 33 | 5.2~7.8 | Static sag 30~40 Reaches max rate around 163mm total |

- [1] Shows active coils, total is 2~3 higher.

- [2] Available travel does not reflect preload.

- [3] This spring will bottom out before the hydraulic anti-bottoming takes effect! But it is so stiff it probably is not a real issue. Race Tech sold these to customers for the GS at various times.

- [4] Rise is indicated in the installed condition, with preload if applicable.

Spacers are used above the spring to set the preload. Preload is traditionally set so that the static sag is about 30% of the total available travel, 65mm in this case. The stock spacers are dark gray plastic tubing.

Oil

The repair manual only specifies "Esso Komfort." In general GS riders seem to be happier with a heavy fork oil (15W) in the left leg. This is probably due to the relatively large openings in the compression valving. For the right leg, 10W is popular. BMW specifies 470ml of oil in each side if the fork has been disassembled. For a regular change, it's 410 left and 440 right.

Because the left damper rod is open at the top but has no holes in the sides, it holds oil when the oil is drained for a simple change. I checked and about 60cc of oil is retained in this fork leg when drained, supporting the specification of 470 for a rebuild and 410 for a refill. The remainder will come out if the fork leg is inverted. Cavitation in the fork leg stops after about 400cc is added; the rest is just to keep the damper assembly functioning in rougher terrain.

Fork tubes, sliders and bushings

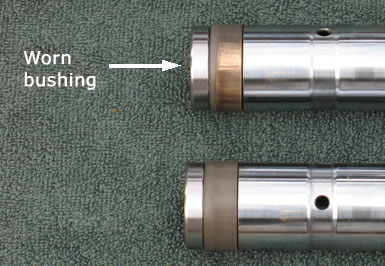

Each fork tube has a bushing sleeve at the bottom, and each slider has a bushing inserted in the opening underneath the fork seal. Normally these parts don't wear very much, but if the fork has been misaligned you may want new ones. In the photo below, the upper fork tube bushing shows distinct wear and should be replaced.

Upgrades

RaceTech Gold Valve cartridge emulators

The Gold Valve inserts are a popular upgrade for street bikes with conventional damper rods (without valves). They work by controlling the secondary oil flow from the top opening in the damper rod via an orifice with a spring-loaded valve. As the fork compresses, the flow gets impeded by this valve. There is a check valve within the Gold Valve that allows unimpeded flow of oil back down the damper rod upon fork extension.

The currently listed kit for the R100GS is the S3804, which contains one valve and an adapter tube.

More information on this modification are on a separate page (coming soon!).

Cartridge upgrades

Rplacing the internals with cartridges is a great way to improve the performance but the options are limited. The original cartridge for these forks was the Marzocchi magnum, sold by BMW under the part numbers 31 42 2 317 539/540 and sold until about 2008 by HPN, but they are no longer available. Adjusters at the top controlled compression in one leg and rebound in the other. Each cylinder has a slot which provides variable compression damping (visible in the close-up). Some riders using similar Marzocchi cartridges have found this to be too progressive, and have modified the cartridge by closing the slot and drilling a series of holes.

A German company called HH race-tech (no relation to the Race Tech in the USA) sells a similar product but their website is pretty poor. Just call or write.

Relatively generic 20mm cartridges are made by other companies such as Traxxion and Andreani which may be adaptable to these forks.

HPN inserts for GS forks (ADVRider thread)

HPN style cartridge inserts for the R100GS (ADVRider)

Cartridges for 40mm forks? (ADVRider thread)

Links

John Chay's BMW fork information page (no link at the moment)